Applications of Agriculture Finish Mower Gearbox

2024-07-25

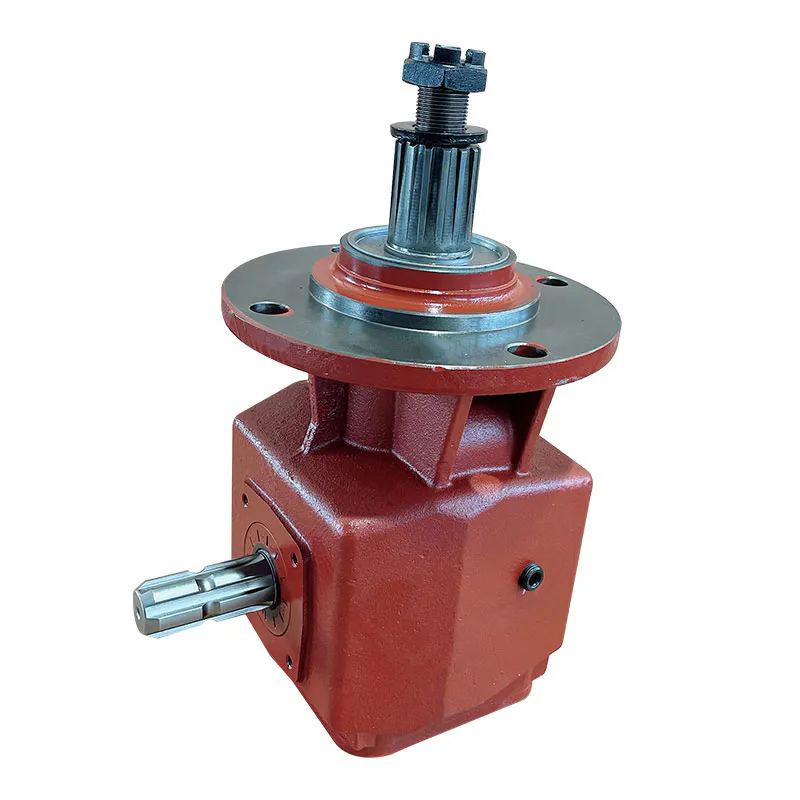

An agriculture finish mower gearbox is a critical component in finish mowers, which are used for lawn and field maintenance. The gearbox is responsible for transmitting power from the tractor to the mower blades, enabling the mower to cut grass and other vegetation efficiently. Here’s a detailed overview of agriculture finish mower gearboxes, including their features, types, maintenance, and applications:

Features

1. Construction:

- Housing: Typically made from heavy-duty cast iron or aluminum to withstand the stresses of operation and provide durability.

- Gears: Consists of high-strength gears, often made from hardened steel or other durable materials, to handle the torque and load.

2. Design:

- Gear Ratio: Features a specific gear ratio that determines the speed and torque delivered to the mower blades. This ratio is crucial for achieving the desired cutting performance.

- Seals and Lubrication: Equipped with seals to prevent contamination and lubrication systems (either oil-filled or grease-packed) to ensure smooth operation and reduce wear.

3. Mounting:

- Attachment: Designed to be mounted on the mower deck and connected to the tractor’s PTO (Power Take-Off) shaft.

- Alignment: Requires precise alignment with the mower blades to ensure efficient power transmission and cutting performance.

4. Cooling:

- Ventilation: May include ventilation or cooling fins to dissipate heat generated during operation.

Types

1. Standard Gearbox:

- Purpose: Used in general-purpose finish mowers for standard lawn and field maintenance.

- Features: Provides a balance of power and speed suitable for most mowing applications.

2. Heavy-Duty Gearbox:

- Purpose: Designed for more demanding applications, such as mowing dense or tall grass.

- Features: Enhanced durability, higher torque capacity, and often features larger gears and bearings.

3. Dual-Speed Gearbox:

- Purpose: Offers multiple speed settings for different mowing conditions.

- Features: Allows the operator to adjust the mower’s cutting speed according to the grass type and mowing conditions.

Applications

1. Lawn Maintenance:

- Residential: Used for maintaining home lawns, ensuring a clean and even cut.

- Commercial: Ideal for maintaining large commercial lawns, parks, and recreational fields.

2. Field Mowing:

- Agricultural: Utilized for mowing pasture fields, hay fields, and other agricultural areas.

- Roadside: Employed for clearing grass along roadsides and highways.

3. Golf Courses:

- Greens: Used for maintaining golf course greens and fairways, providing a high-quality finish.

Benefits

1. Efficient Power Transfer:

- Ensures effective transfer of power from the tractor to the mower blades, resulting in consistent cutting performance.

2. Durability:

- Designed to withstand the rigors of frequent use, providing long-lasting reliability.

3. Adjustability:

- Some models offer adjustable speed settings or gear ratios to adapt to different mowing conditions.

4. Smooth Operation:

- Properly designed gearboxes ensure smooth and efficient operation, reducing vibration and noise.

Maintenance and Care

1. Regular Inspection:

- Check for signs of wear, damage, or leakage. Inspect gears and bearings for proper operation.

2. Lubrication:

- Ensure the gearbox is properly lubricated according to the manufacturer’s recommendations. Refill or replace lubricant as needed.

3. Cleaning:

- Keep the gearbox clean and free from debris. Wipe down the exterior and remove any buildup around the gearbox area.

4. Alignment:

- Ensure that the gearbox is properly aligned with the mower blades and PTO shaft to prevent undue wear and damage.

5. Seals:

- Check seals regularly for signs of wear or leakage. Replace seals if they become damaged to prevent contamination.

6. Storage:

- Store the mower and gearbox in a dry, clean environment to prevent rust and corrosion.

Troubleshooting

1. Noise:

- Issue: Excessive noise may indicate worn gears or inadequate lubrication.

- Solution: Inspect and replace worn parts, and ensure proper lubrication.

2. Overheating:

- Issue: Overheating may be caused by insufficient lubrication or excessive load.

- Solution: Check the lubricant level and ensure the gearbox is not overloaded.

3. Vibration:

- Issue: Excessive vibration may result from misalignment or damaged components.

- Solution: Check alignment and replace damaged parts as needed.

Conclusion

The agriculture finish mower gearbox is a vital component in maintaining efficient and effective mowing operations. Its design, durability, and proper maintenance are essential for achieving optimal performance and longevity. Understanding the features, types, and care requirements of the gearbox will help ensure that it functions reliably and provides high-quality results in various mowing applications.