Considerations of Electoral Magnet Valve

2024-06-18

An electoral magnet valve appears to be a misinterpretation or a typo. It's more likely you meant "electromagnetic valve" or "solenoid valve," which are common terms in engineering and industrial contexts. Here’s an overview of what an electromagnetic valve or solenoid valve is:

Electromagnetic Valve (Solenoid Valve) Overview

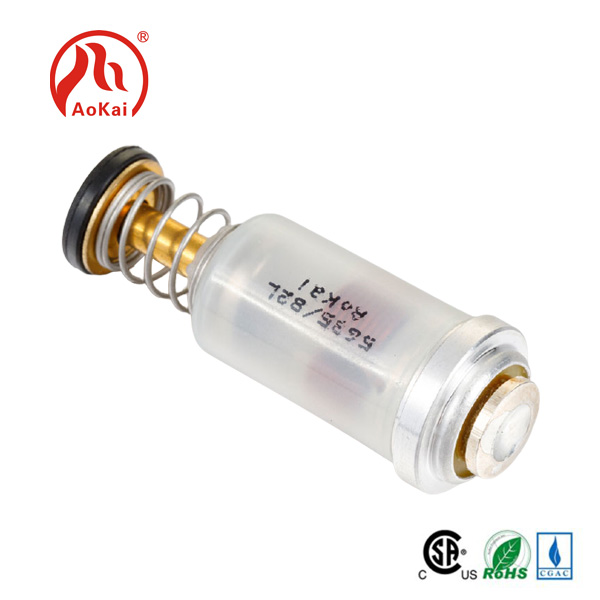

An electromagnetic valve, often referred to as a solenoid valve, is an electromechanical device used to control the flow of liquids or gases in a system. It operates by using an electromagnetic coil to actuate a plunger mechanism, which opens or closes the valve. Here are the key aspects:

Functionality

1. Operation: When an electrical current is applied to the coil (electromagnet), it generates a magnetic field that moves the plunger. This action either allows or blocks the flow of fluid through the valve.

2. Types:

- Normally Closed (NC): In its resting state (no power), the valve is closed, and it opens when electrical power is applied.

- Normally Open (NO): In its resting state, the valve is open, and it closes when electrical power is applied.

- Three-Way Solenoid Valves: Can either mix or divert fluids depending on the application.

3. Applications:

- Fluid Control: Used in various industries for controlling water, air, gas, steam, oil, and other fluids.

- Automation: Integrated into automated systems where precise control of fluid flow is required, such as in industrial processes, HVAC systems, medical equipment, and automotive applications.

- Safety and Emergency Shutoff: Used in safety systems to quickly shut off fluid flow in emergencies.

4. Advantages:

- Fast Response: Actuates quickly in response to electrical signals, enabling rapid changes in fluid flow.

- Reliability: Simple design with few moving parts, leading to reliable operation over long periods.

- Energy Efficiency: Consumes power only when changing state, reducing energy consumption compared to continuously operated valves.

5. Materials and Construction:

- Materials: Typically constructed from materials such as stainless steel, brass, or plastic, depending on the fluid being controlled and environmental conditions.

- Sizes: Available in various sizes to accommodate different flow rates and pressure requirements.

Considerations

- Compatibility: Ensure the solenoid valve is compatible with the fluid type, pressure, temperature, and environmental conditions of the application.

- Installation: Proper installation and maintenance are crucial to ensure optimal performance and longevity.

- Voltage: Select the appropriate voltage and electrical specifications (AC or DC) for the solenoid valve based on the application requirements.

- Control: May require additional control components such as timers, relays, or controllers to integrate with automated systems effectively.

Conclusion

Electromagnetic valves (solenoid valves) play a critical role in controlling the flow of fluids in a wide range of industrial and commercial applications. Understanding their operation, types, applications, and considerations is essential when selecting and using them in various engineering and manufacturing processes. If you were referring to a different type of valve or have specific application requirements, please provide more details for further assistance.