Considerations related to aluminum enclosures

2024-01-04

An aluminum enclosure refers to a protective casing or housing made primarily from aluminum. Aluminum enclosures are commonly used in various industries to house electronic components, devices, or equipment, providing protection against environmental factors, electromagnetic interference, and physical damage. These enclosures are valued for their lightweight yet durable properties, corrosion resistance, and excellent thermal conductivity.

Here are key features and considerations related to aluminum enclosures:

1. Material Properties:

- Aluminum is chosen for enclosure construction due to its lightweight nature, corrosion resistance, and excellent thermal conductivity. It provides a good balance between strength and weight, making it suitable for various applications.

2. Corrosion Resistance:

- Aluminum naturally forms a protective oxide layer, providing corrosion resistance. This is especially important for outdoor or harsh environments where exposure to moisture and other elements can be a concern.

3. Thermal Conductivity:

- Aluminum has high thermal conductivity, allowing for effective heat dissipation. This property is beneficial for enclosures housing electronic components that generate heat during operation.

4. Weight:

- Aluminum is lightweight compared to other metals, making it suitable for applications where weight is a critical factor, such as in portable devices or equipment.

5. Strength:

- While aluminum is lightweight, it still offers sufficient strength for many enclosure applications. The alloy and manufacturing process can be tailored to meet specific strength requirements.

6. EMI Shielding:

- Aluminum enclosures can provide electromagnetic interference (EMI) shielding, protecting sensitive electronic components from external electromagnetic radiation and preventing emissions from the enclosed equipment.

7. Surface Finishes:

- Aluminum enclosures can be finished in various ways, including anodizing, powder coating, or painting. These finishes not only enhance the aesthetic appearance but also provide additional protection against corrosion and wear.

8. Customization and Modularity:

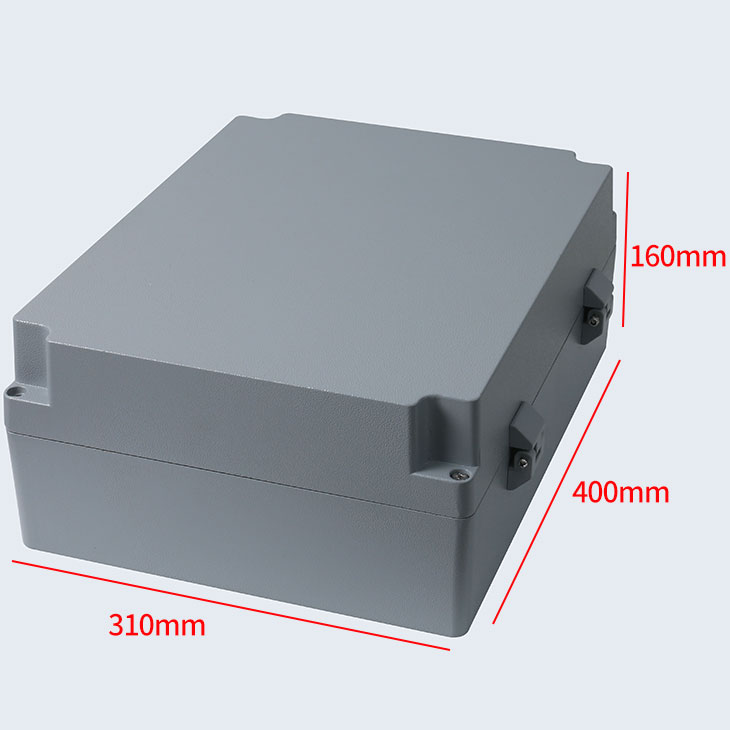

- Aluminum enclosures can be customized to meet specific size, shape, and feature requirements. They may also be designed with modularity in mind, allowing for the assembly of complex systems from standardized components.

9. Environmental Sealing:

- Some aluminum enclosures are designed with gaskets, seals, or other weatherproofing features to protect the enclosed components from dust, water, and other environmental factors.

10. Applications:

- Aluminum enclosures are used in a wide range of applications, including electronics, telecommunications, aerospace, automotive, medical devices, and industrial equipment. They can house circuit boards, sensors, controls, and other electronic or mechanical components.

11. Cost-Effective Manufacturing:

- Aluminum enclosures can be manufactured using cost-effective methods such as extrusion or die casting, making them an economical choice for mass production.

12. Mounting Options:

- Enclosures often include mounting options, such as flanges, brackets, or DIN rails, to facilitate easy installation and integration into larger systems.

Aluminum enclosures play a crucial role in protecting sensitive equipment and electronic components across various industries. Their versatile properties make them a popular choice for manufacturers seeking a balance between durability, weight, and thermal performance.