PET Preform Mold: The Key to Efficient Bottle Manufacturing

2025-06-18

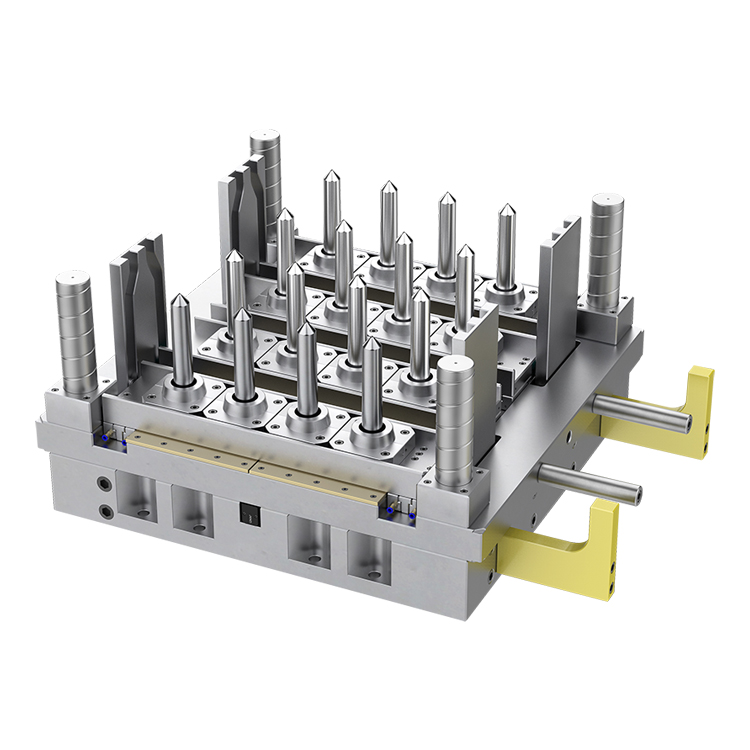

In the world of plastic bottle production, PET preform molds play a crucial role. These specialized molds are used to create PET preforms — the small, test-tube-shaped pieces that are later blown into full-sized bottles. Whether for beverages, cosmetics, or household products, PET preform molds ensure precision, quality, and efficiency in manufacturing.

In this blog, we’ll explore what PET preform molds are, how they work, and why they are vital for the packaging industry.

What Is a PET Preform Mold?

A PET preform mold is a precision-engineered tool used in injection molding machines to produce PET preforms. The mold shapes molten polyethylene terephthalate (PET) resin into the exact form and size required for subsequent blow molding into bottles.

How Does the PET Preform Mold Work?

The injection molding process involves heating PET resin pellets until molten, then injecting the material into the preform mold cavity under high pressure. The mold cools the resin quickly, solidifying it into a preform with accurate dimensions. After molding, the preforms are ejected and sent to blow molding machines to be expanded into bottles.

Key Features of PET Preform Molds

Precision Engineering: High accuracy ensures uniform thickness and weight for consistent bottle quality.

Durability: Made from hardened steel or other robust materials to withstand high pressure and temperature cycles.

Cooling Systems: Integrated channels help regulate mold temperature for efficient cycle times.

Multi-Cavity Design: Molds often have multiple cavities to produce several preforms per cycle, boosting productivity.

Customizable: Designs can be tailored for different bottle shapes, sizes, and neck finishes.

Why Are PET Preform Molds Important?

Quality Control: A good mold guarantees preforms with uniform properties, preventing defects in final bottles.

Efficiency: Faster molding cycles and multi-cavity designs increase production speed and reduce costs.

Material Savings: Precision molds minimize resin waste by controlling preform weight accurately.

Versatility: Molds support a wide range of bottle designs, catering to diverse market demands.

Applications of PET Preform Molds

Beverage Industry: Bottles for water, soda, juices, and alcoholic drinks.

Cosmetics: Containers for lotions, shampoos, and perfumes.

Household Products: Bottles for cleaning supplies and detergents.

Pharmaceuticals: Packaging for medicines and health supplements.

Maintenance Tips for PET Preform Molds

Regular Cleaning: Prevent resin buildup and contamination.

Inspection: Check for wear, cracks, or corrosion to avoid production issues.

Proper Storage: Store molds in controlled environments to prevent damage.

Timely Repairs: Address any defects promptly to maintain mold performance.

Final Thoughts

PET preform molds are essential tools that ensure high-quality, efficient, and cost-effective bottle production. Investing in well-designed molds and proper maintenance can significantly enhance manufacturing outcomes and product reliability.

If you’re in the packaging industry or looking to start PET bottle production, understanding and choosing the right PET preform mold is a key step toward success.