The Advantages of UV Printing on Alucobond Panels

2024-08-23

In the world of modern architecture and design, Alucobond panels have emerged as a popular choice for both interior and exterior applications. Known for their durability, lightweight properties, and sleek appearance, these aluminum composite panels are widely used in everything from building facades to signage. However, the true potential of Alucobond panels is unlocked when combined with UV printing technology. In this blog, we’ll explore what UV printing on Alucobond is, its benefits, and how it’s transforming the design and construction industries.

What is Alucobond?

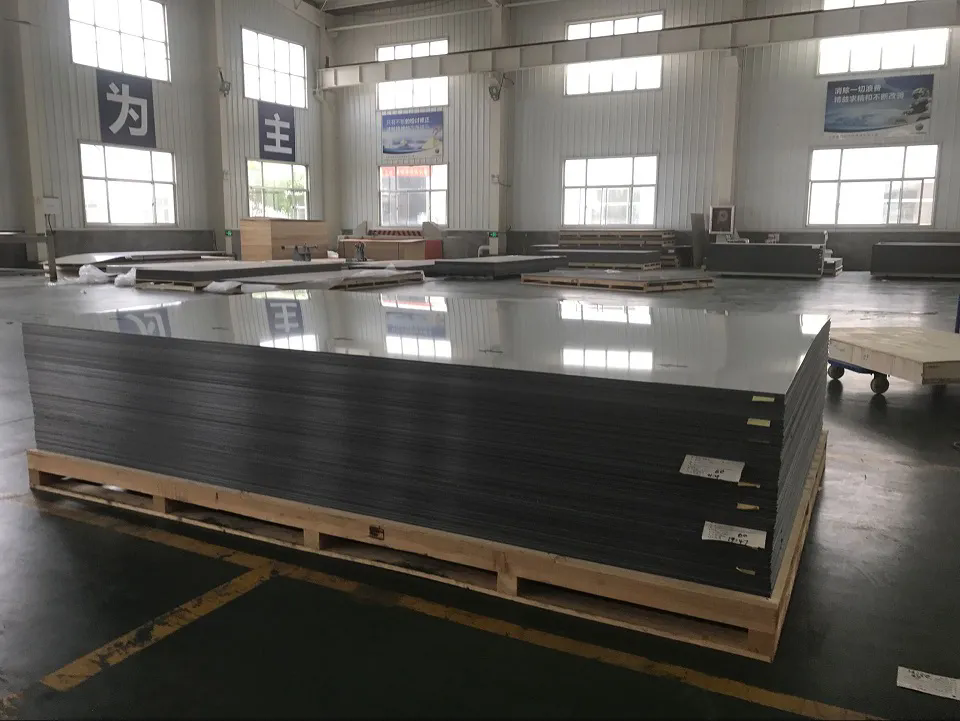

Alucobond is a brand of aluminum composite material (ACM) that consists of two thin layers of aluminum enclosing a non-aluminum core. This combination results in a lightweight, yet rigid and durable panel that is highly resistant to weathering, corrosion, and impact. Alucobond panels are known for their smooth surface and are available in a variety of colors and finishes, making them ideal for architectural cladding, signage, and interior design projects.

What is UV Printing?

UV printing is a digital printing process that uses ultraviolet (UV) light to cure or dry the ink as it is printed. Unlike traditional printing methods that rely on solvents to evaporate, UV printing uses special inks that solidify instantly when exposed to UV light. This results in vibrant, high-resolution images that are durable and resistant to fading, scratching, and chemical exposure.

The Benefits of UV Printing on Alucobond

1. High-Quality, Durable Prints

One of the most significant advantages of UV printing on Alucobond is the exceptional quality of the prints. The UV curing process ensures that the ink adheres perfectly to the smooth surface of the Alucobond panel, producing sharp, vibrant images with high resolution. These prints are highly resistant to fading, even when exposed to harsh environmental conditions, making them ideal for outdoor applications.

2. Customizable Designs

UV printing offers unparalleled flexibility in design. Whether you need intricate patterns, detailed graphics, or photographic images, UV printing on Alucobond allows for full customization. This opens up endless possibilities for architects, designers, and marketers looking to create unique and impactful visual displays.

3. Weather and UV Resistance

Alucobond panels are already known for their durability and resistance to the elements. When combined with UV printing, the printed images gain an additional layer of protection. The UV-cured inks are not only resistant to fading from sunlight but also to moisture, chemicals, and temperature fluctuations. This makes UV-printed Alucobond panels a perfect choice for outdoor signage, building facades, and any application where long-term exposure to the elements is a concern.

4. Environmentally Friendly

UV printing is an environmentally friendly option compared to traditional solvent-based printing methods. The UV curing process emits very low levels of volatile organic compounds (VOCs), reducing the environmental impact. Additionally, the instant curing process minimizes waste and energy consumption, making it a more sustainable choice for large-scale printing projects.

5. Fast Turnaround and Cost-Effective

UV printing on Alucobond is a relatively fast process, with the instant curing of the ink allowing for quick production times. This is especially beneficial for projects with tight deadlines. Additionally, because UV printing eliminates the need for drying time and reduces material waste, it can be more cost-effective than other printing methods, particularly for large-scale or high-volume projects.

Applications of UV Printed Alucobond

The combination of Alucobond panels and UV printing opens up a wide range of applications across various industries:

- Architectural Facades: UV printing allows for the creation of stunning, custom-designed building facades that can feature anything from company logos to intricate designs that enhance the visual appeal of a structure.

- Signage: The durability and vibrant color of UV-printed Alucobond make it an ideal choice for outdoor signage, including billboards, wayfinding signs, and commercial displays.

- Interior Design: UV-printed Alucobond panels can be used to create striking wall coverings, decorative elements, and branded environments within commercial spaces, offices, and retail stores.

- Exhibition and Display: For trade shows, exhibitions, and events, UV-printed Alucobond panels provide a durable and visually impressive medium for creating booths, backdrops, and displays that stand out.

- Art Installations: The high-quality, customizable nature of UV printing makes it a popular choice for artists and designers looking to create large-scale art installations on durable, weather-resistant panels.

Conclusion

UV printing on Alucobond panels represents a powerful combination of technology and material innovation, offering unmatched quality, durability, and customization options. Whether for architectural facades, signage, interior design, or creative displays, UV-printed Alucobond panels provide a versatile and long-lasting solution that meets the demands of modern design and construction. As the technology continues to evolve, we can expect to see even more creative applications of UV-printed Alucobond in the future, further pushing the boundaries of what’s possible in visual communication and design.