What Is Plastic Sheet Equipment and Why Is It Important?

2025-07-09

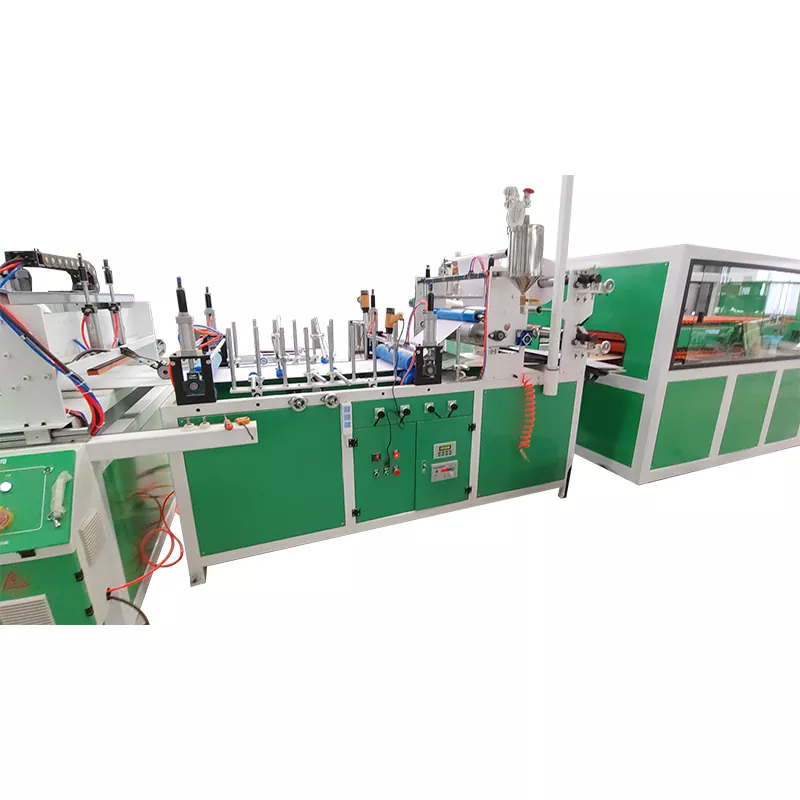

Plastic sheet equipment refers to the machinery and tools used to manufacture, process, and handle plastic sheets. These sheets are versatile materials widely used in packaging, construction, automotive, signage, and many other industries. The equipment involved plays a crucial role in ensuring quality, efficiency, and precision in plastic sheet production and fabrication.

What Types of Plastic Sheet Equipment Are There?

Plastic sheet equipment encompasses a range of machines designed for different stages of plastic sheet production and processing:

1. Extrusion Machines:

Used to produce plastic sheets by melting raw plastic pellets and shaping them into flat sheets through a die.

Includes single-screw or twin-screw extruders with chill rollers for cooling.

2. Calendering Machines:

Roll plastic material between heavy rollers to create sheets with uniform thickness and smooth surfaces.

Commonly used for PVC, rubber, and other thermoplastic sheets.

3. Cutting Machines:

Equipment such as guillotines, rotary cutters, or laser cutters used to trim plastic sheets to desired sizes.

4. Thermoforming Machines:

Heat plastic sheets to a pliable state and mold them into specific shapes for packaging or product components.

5. Laminating Machines:

Bond plastic sheets with other materials like films or foils to enhance properties like strength, appearance, or barrier performance.

6. Printing Machines:

Print designs or text on plastic sheets for branding or decorative purposes.

What Materials Are Processed with Plastic Sheet Equipment?

Common plastic sheet materials include:

Polycarbonate (PC)

Polyvinyl Chloride (PVC)

Acrylic (PMMA)

Polyethylene (PE)

Polypropylene (PP)

ABS (Acrylonitrile Butadiene Styrene)

What Are the Benefits of Using Plastic Sheet Equipment?

High Precision:Ensures consistent thickness and surface quality.

Scalability:Enables mass production to meet various industry demands.

Versatility:Handles a wide range of plastic types and sheet sizes.

Customization:Allows for specific thickness, texture, color, and size specifications.

Cost-Effective:Efficient production reduces waste and lowers material costs.

Where Is Plastic Sheet Equipment Used?

Packaging Industry:For blister packs, clamshells, and protective covers.

Construction:Wall panels, roofing sheets, and insulation boards.

Automotive:Interior panels, light diffusers, and protective covers.

Signage and Displays:Acrylic sheets for signs, light boxes, and exhibition stands.

Electronics:Enclosures and component shields.

How to Choose the Right Plastic Sheet Equipment?

Consider the following factors:

1. Material Compatibility:Ensure the equipment supports the types of plastic you intend to process.

2. Production Capacity:Match the machine size and speed with your output requirements.

3. Precision and Quality:Look for equipment with advanced controls for consistent results.

4. Automation Level:Automated machines improve efficiency and reduce labor costs.

5. After-Sales Support:Reliable service and parts availability are critical for minimizing downtime.

Conclusion

Plastic sheet equipment is vital for producing high-quality plastic sheets used across numerous industries. Selecting the appropriate machinery tailored to your material and production needs can enhance product quality, improve operational efficiency, and reduce costs.