Why Are Stainless Steel Flanges Essential for Industrial Systems?

2024-12-26

Stainless steel flanges may seem like a simple mechanical component, but they play a crucial role in connecting pipes, valves, and other equipment in a variety of industrial systems. Whether you're working in oil and gas, water treatment, or even food processing, these flanges are often the backbone of your operations. But what makes stainless steel flanges so essential for industrial systems? Let's explore their significance and why they are a popular choice in the world of engineering.

1. What Are Stainless Steel Flanges?

Stainless steel flanges are mechanical components used to connect pipes, pumps, valves, and other equipment in a piping system. They provide a strong, reliable seal to prevent leaks and ensure the smooth transfer of fluids and gases. Flanges are typically used to join sections of pipes, allowing easy access for maintenance or inspection.

2. Why Choose Stainless Steel for Flanges?

Stainless steel flanges offer several advantages over other materials, making them the go-to choice for many industrial applications:

- Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, making it ideal for applications involving water, chemicals, or extreme temperatures.

- Strength and Durability: Stainless steel is known for its strength and ability to withstand high pressure and heavy loads, making it perfect for high-stress environments.

- Longevity: Due to its resistance to wear and corrosion, stainless steel flanges have a longer lifespan, saving on maintenance and replacement costs.

- Easy Maintenance: Stainless steel flanges are easy to clean and maintain, ensuring that they remain functional and safe in various industries.

3. What Industries Use Stainless Steel Flanges?

Stainless steel flanges are widely used across many industries, thanks to their versatility and durability. Some key sectors include:

- Oil and Gas: Used to connect pipelines and prevent leaks in offshore rigs, refineries, and gas processing plants.

- Chemical Processing: Stainless steel’s resistance to corrosion and harsh chemicals makes it ideal for chemical reactors and processing units.

- Food and Beverage: Stainless steel flanges are commonly used in food processing plants due to their hygiene properties and ease of cleaning.

- Water Treatment: Stainless steel is often used in water treatment plants for both fresh and wastewater systems due to its resistance to corrosion from water and chemicals.

- Pharmaceuticals: Stainless steel flanges help maintain sterile conditions in pharmaceutical manufacturing and packaging.

4. How Are Stainless Steel Flanges Installed?

Installing stainless steel flanges is a relatively straightforward process, but it must be done carefully to ensure a proper seal. The installation process typically involves:

- Aligning the Flanges: The flanges must be aligned perfectly to ensure a secure connection.

- Gasket Placement: A gasket is often placed between the two flanges to create a leak-proof seal.

- Bolt Tightening: Bolts are used to secure the flanges together, ensuring a tight connection. Proper torque is essential to avoid leaks.

- Testing: Once installed, the flange connections should be tested for leaks before putting the system into full operation.

5. What Are the Different Types of Stainless Steel Flanges?

There are various types of stainless steel flanges, each designed for specific applications:

- Weld Neck Flanges: These are welded to the pipe and offer high strength and resistance to pressure.

- Slip-On Flanges: Easier to install and suitable for low-pressure systems, slip-on flanges are commonly used in general-purpose applications.

- Blind Flanges: Used to seal the end of a pipe or a valve opening, blind flanges are essential for closing off sections of a piping system.

- Threaded Flanges: These flanges have internal threads and are screwed onto pipes, making them ideal for applications that require easy disassembly.

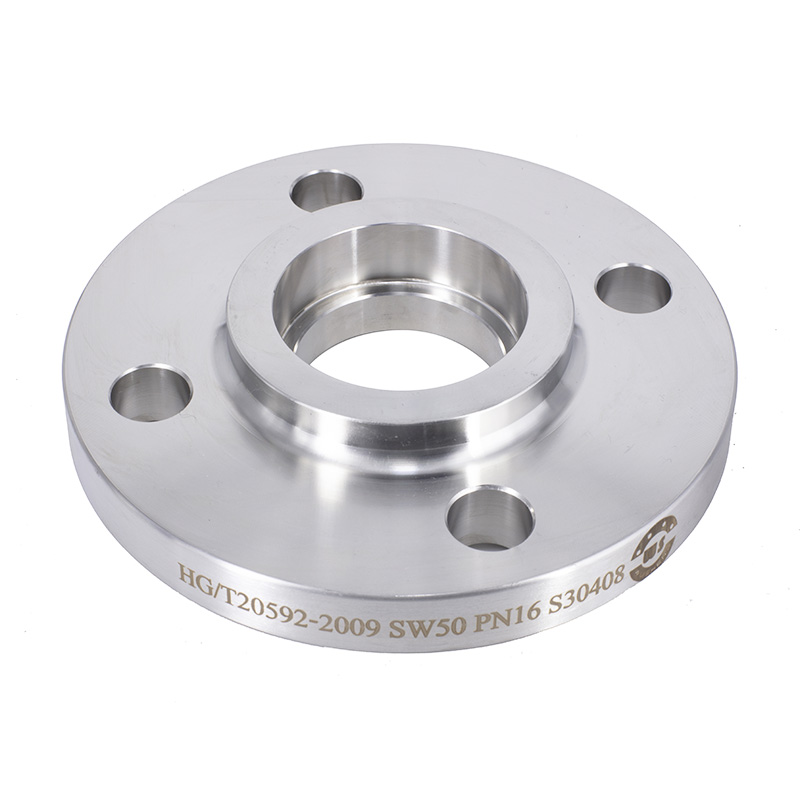

- Socket Weld Flanges: Designed for high-pressure systems, socket weld flanges are used in applications where the pipe is inserted into the flange for a secure, tight fit.

6. How Do You Maintain Stainless Steel Flanges?

Maintaining stainless steel flanges ensures their long-term performance and reliability. Some maintenance tips include:

- Regular Inspection: Periodically inspect flanges for signs of damage, corrosion, or wear, especially in high-pressure or high-temperature systems.

- Cleaning: Keep the flanges clean and free of debris, as dirt and buildup can affect the seal and function.

- Check Bolts: Ensure that bolts are tight and properly torqued to maintain a secure connection.

- Lubrication: Use suitable lubricants on bolts and threads to prevent rusting and facilitate easier disassembly when needed.

Final Thoughts

Stainless steel flanges are an indispensable part of any industrial piping system. Their strength, corrosion resistance, and versatility make them ideal for a wide range of applications, from the oil and gas industry to food processing. Understanding the role of stainless steel flanges and how to select the right one for your system is crucial for ensuring safety, efficiency, and longevity.